-

Konfor Klima Santralleri

Isıtma soğutma yapabilir...

-

Hijyenik Klima Santralleri

Taze hava şartlandırıcı...

-

Isı Geri Kazanım Üniteleri

Hava şartlandırma prosesleri...

-

Mutfak Egzoz Üniteleri

%100 taze hava kazanımı...

-

Sığınak Üniteleri

Filtrelenmiş taze hava...

-

Aspiratör Üniteleri

Hava sirkülasyonu...

Mutfak Egzoz Üniteleri

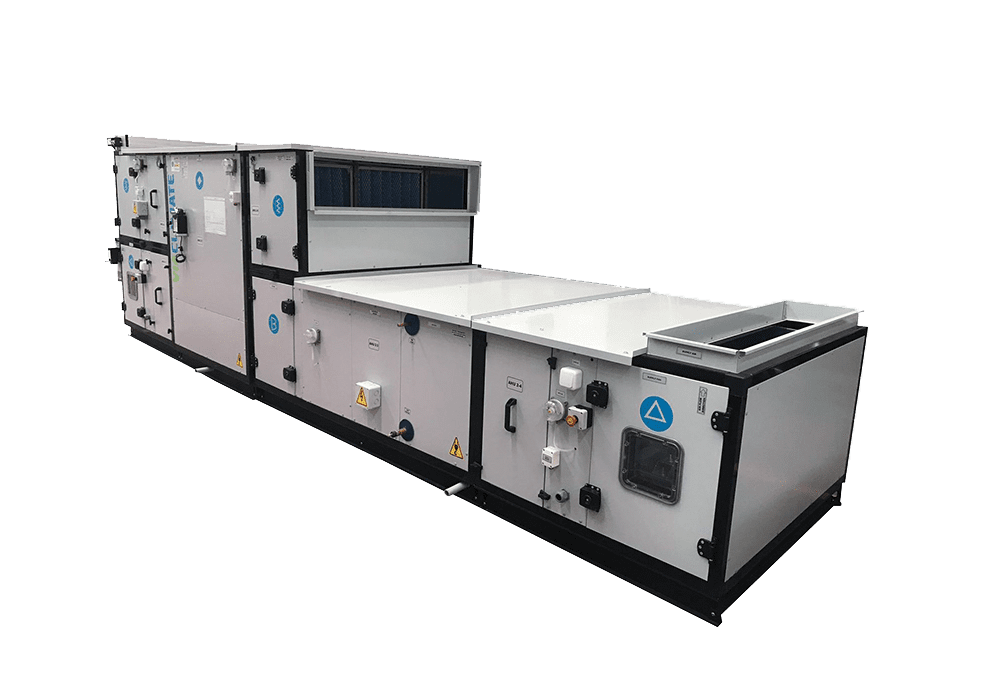

Viaclimate markalı mutfak egzoz üniteleri endüstriyel mutfaklarda, pişirme esnasında oluşan yağ, duman ve kokuyu ortamdan egzoz etmek için kullanılır. Mutfak egzoz ünitelerinin çalışma alanları, ortamdaki duman, koku ve yağ yoğunluğuna bağlı olarak dört ana başlık altında toplanır. Düşük yoğunlukta, orta yoğunlukta, yüksek yoğunlukta, çok yüksek yoğunlukta mutfaklar için kademe kademe; metal filtre, aktif karbon filtre ve elektrostatik filtre kullanılır.

Viaclimate mutfak egzoz üniteleri, kirli havayı yoğunluğuna bağlı olarak filtreleme, ortam havasının egzozu, taze hava beslemesi, soğutma, ısı geri kazanım durumuna göre 3 farklı şekilde tasarlanır.

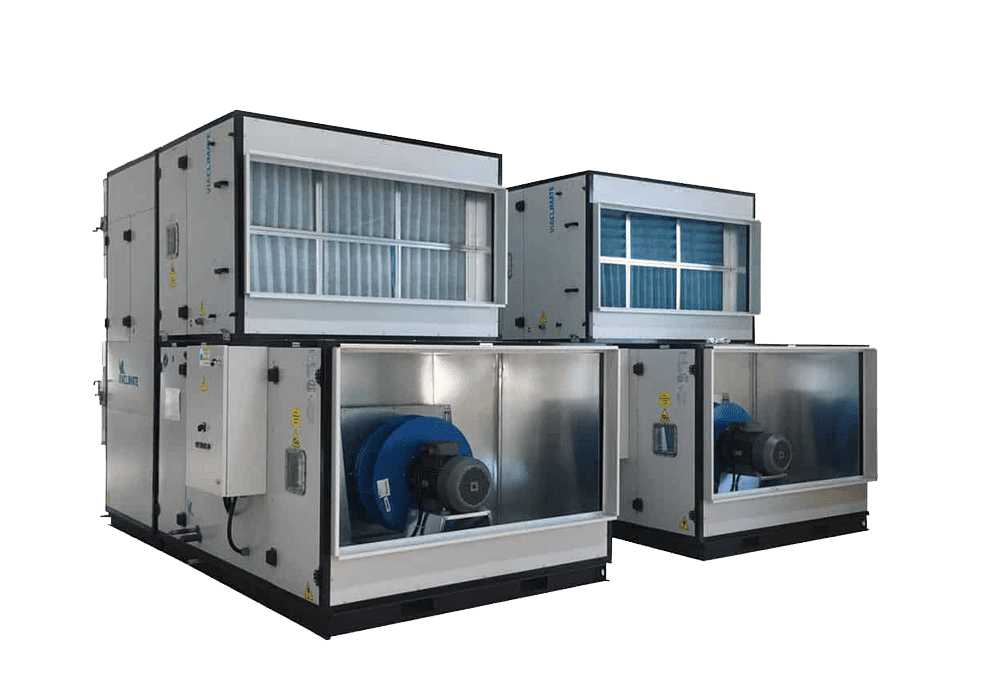

Viaclimate markalı mutfak egzoz üniteleri üç çeşittir.

- Mutfak Egzoz Fanı (ViacleanS)

- Mutfak Egzoz Santrali (ViacleanM)

- 100% Taze Havalı Isı Geri Kazanımlı Mutfak Klima ve Egzoz Santralleri (ViacleanL)