-

Konfor Klima Santralleri

Isıtma soğutma yapabilir...

-

Hijyenik Klima Santralleri

Taze hava şartlandırıcı...

-

Isı Geri Kazanım Üniteleri

Hava şartlandırma prosesleri...

-

Mutfak Egzoz Üniteleri

%100 taze hava kazanımı...

-

Sığınak Üniteleri

Filtrelenmiş taze hava...

-

Aspiratör Üniteleri

Hava sirkülasyonu...

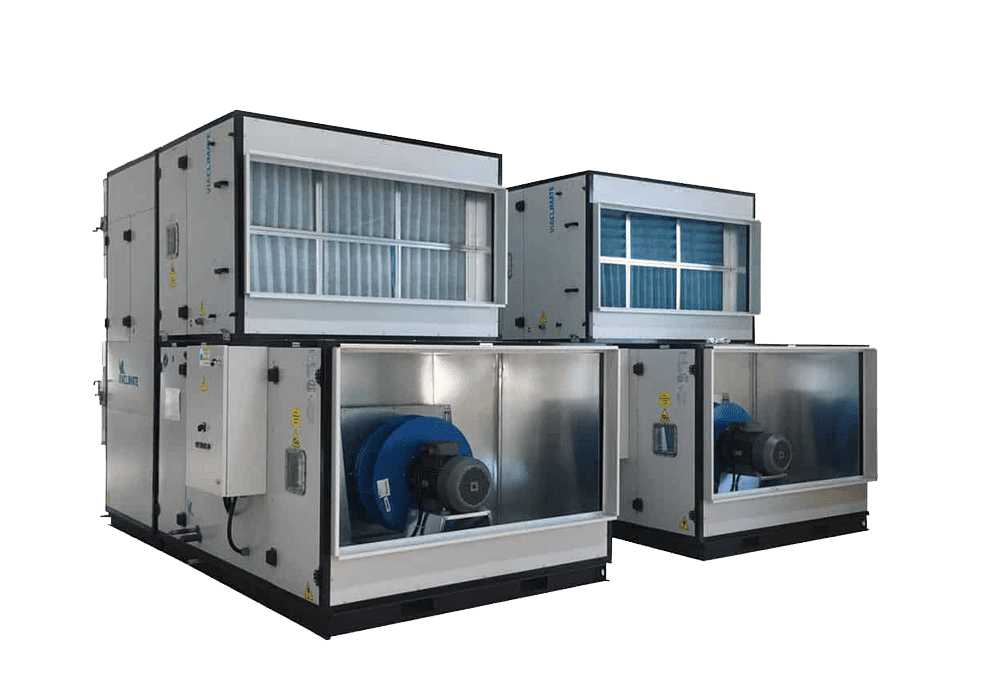

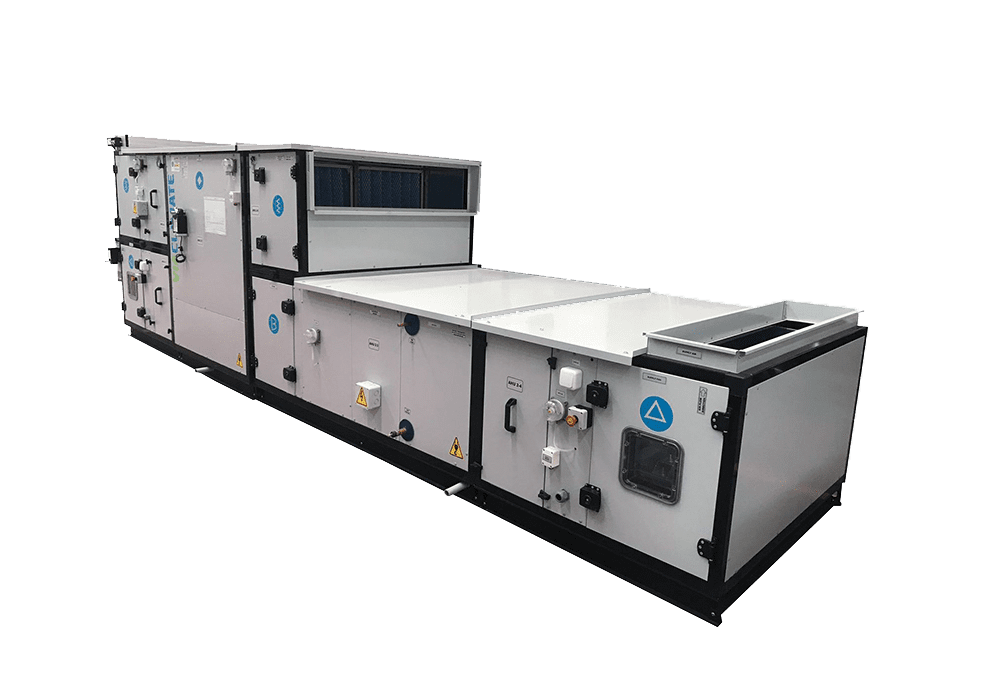

Konfor Klima Santralleri

Viaclimate markalı konfor klima santrali çeşitleri hijyenik olmayan ortamların taze hava beslemesi, ortam havasının egzozu, ısıtma, soğutma, nemlendirme, hava filtreleme, ısı geri kazanım durumlarına göre dört farklı şekilde tasarlanır.

Konfor klima santralleri havayı şartlandırması için dış ünitelere ihtiyacı vardır. Bunlar; sıcak su kazanları, vrf dış üniteler, su soğutma grupları, ısıtma için elektrik enerjisi, condansing dış ünite gibi üniteler sayesinde ısıtma veya soğutma yapabilir.

Önceki

Sonraki

Viaclimate markalı konfor klima santralleri dört çeşittir.

- 100% Taze Hava Şartlandırıcı Klima Santralleri

- 100% Taze Havalı Isı Geri Kazanımlı Klima Santralleri

- Kısmi (Karışım) Havalı Klima Santralleri

- Kısmi Taze havalı ve Isı geri Kazanımlı Klima Santralleri