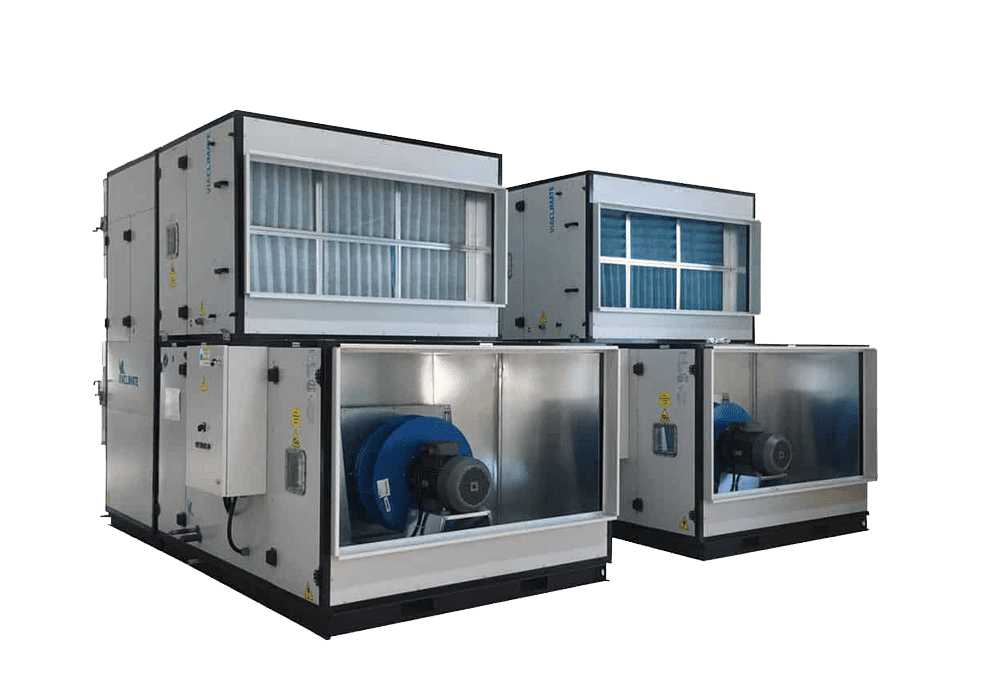

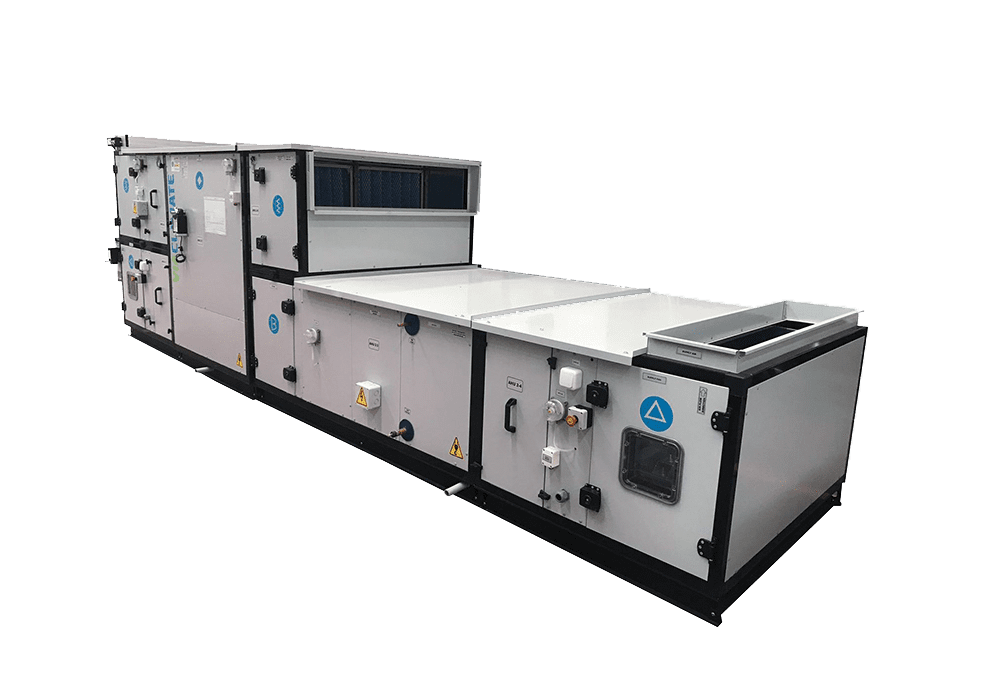

Çatı Tipi Paket Klima

Viaclimate markalı çatı tipi paket klimalar, soğutma veya ısıtma çevriminin tümüyle aynı ünite içerisinde gerçekleştiği kompakt ve birleşik hava şartlandırıcılardır. Viaclimate Rooftop, taze hava beslemesi, ortam havasının egzozu, hava filtreleme, ısıtma, soğutma, ısı geri kazanım gibi hava şartlandırma proseslerini gerçekleştirerek çalışır.

Çatı Tipi Paket Klimalar havayı şartlandırması için dış ünitelere ihtiyaç duymazlar. Isıtma işlevi cihazın tersine çevrimle ısı pompası olarak çalıştırılmasının yanında, elektrikli ısıtıcı, sıcak su bataryası veya gaz yakma modülü kullanılarak sağlanır.

Viaclimate markalı çatı tipi paket klimalar düşük işletme maliyetiyle, yüksek verimle çalışmaya olanak sağlar. Çatı tipi klima cihazları elektrik otomasyonu ve kompakt dizaynları sayesinde tak-çalıştır mantığında uygulamaya yönelik kullanılma en uygun cihazlardır.