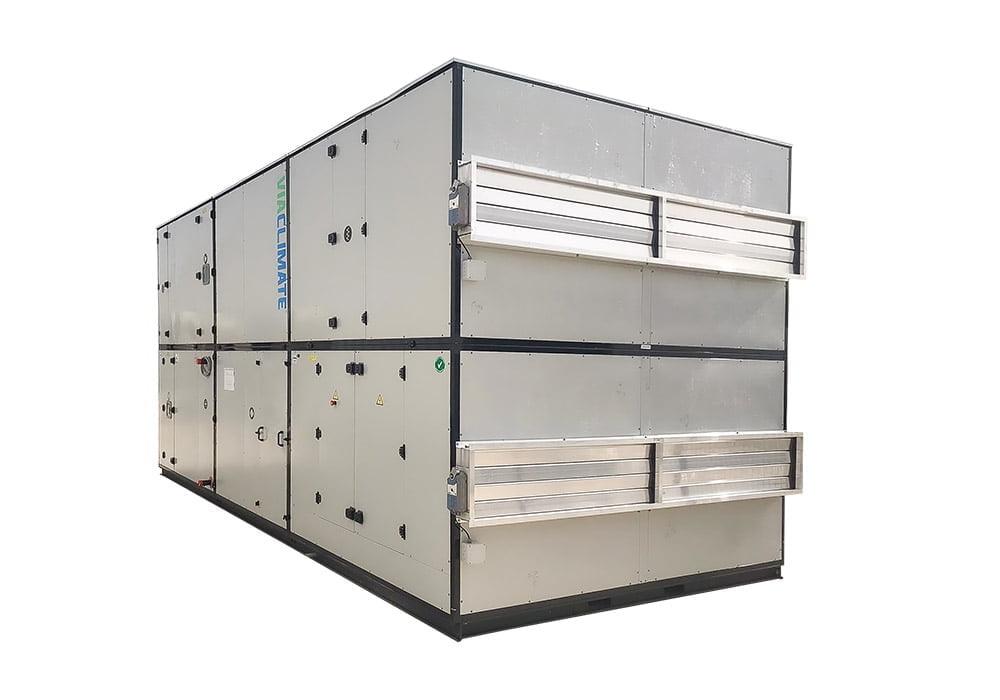

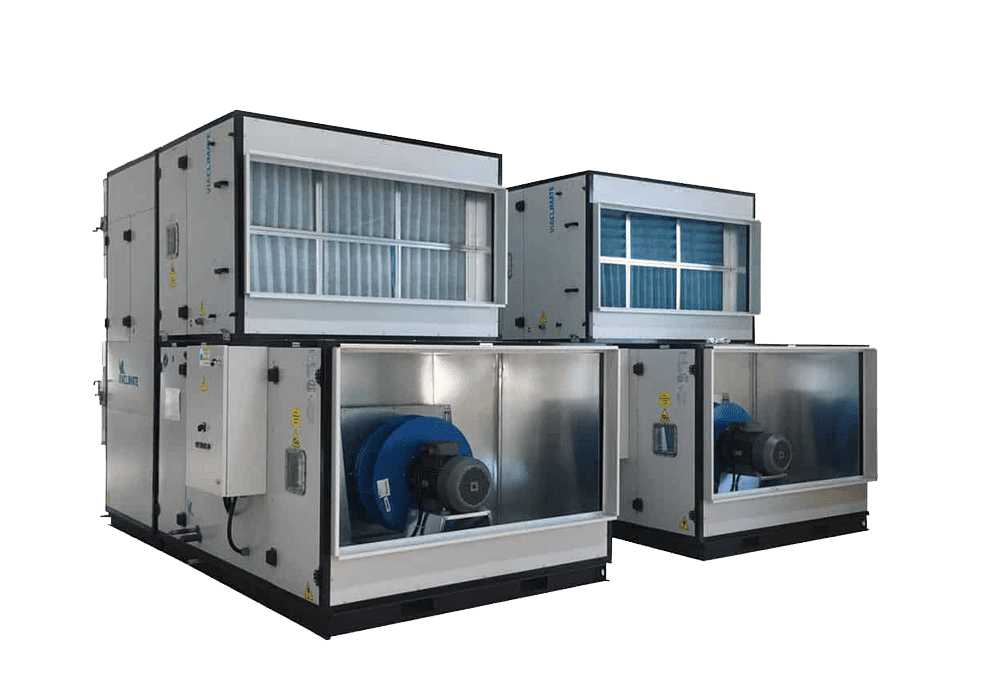

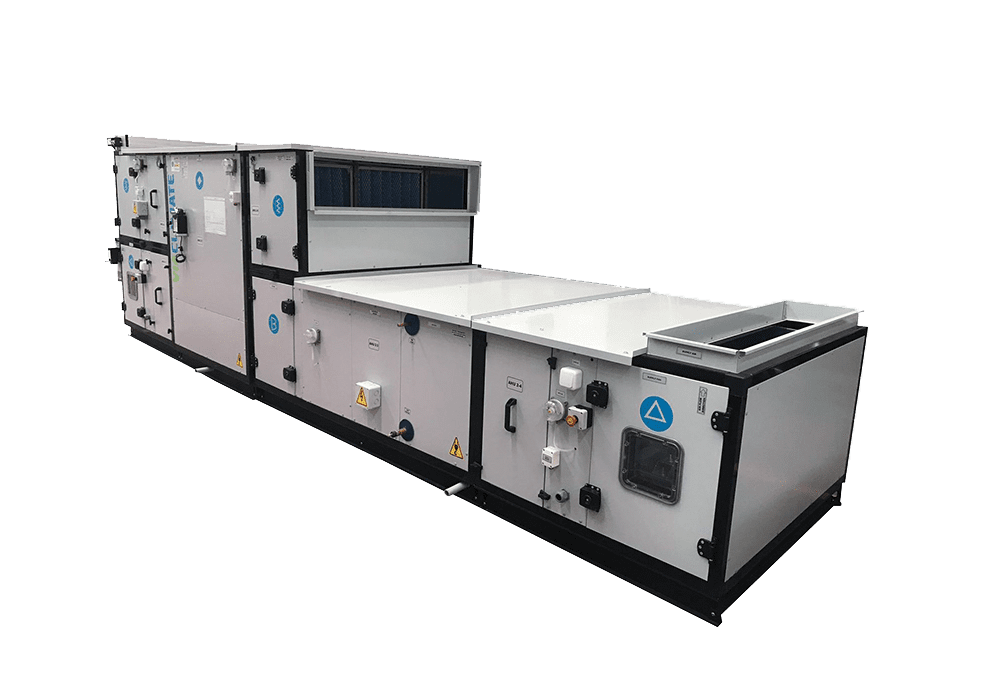

Havuz Nem Alma Santrali

Viaclimate markalı havuz nem alma santralleri kapalı havuzlarda, VDI 2089 standartlarına uygun olarak nemi ve taze hava miktarını kontrol altında tutar ve mahalin konfor seviyesine ulaşmasını sağlayan paket tip cihazlardır. Kapalı yüzme havuzlarında nem oranının VDI 2089’a göre %40 – %64 değerleri arasında olması gerekmektedir. Nem oranının %64 değerinin üzerine çıkması ortamda mikrop, bakteri ve mantar gibi mikroorganizmaların oluşumuna ve çoğalmasına neden olmaktadır. VIAPOOL, bu tür olumsuz etkileri ortadan kaldırır. VIAPOOL, ortamdaki fazla nemin uzaklaştırılması, taze hava beslemesi, ortam havasının egzozu, hava filtreleme, ısıtma, ısı geri kazanım gibi hava şartlandırma proseslerini gerçekleştirerek çalışır. Viaclimate markalı havuz nem alma santralleri elektrik otomasyonu ve kompakt dizaynları sayesinde tak-çalıştır mantığında uygulamaya yönelik kullanılma uygun cihazlardır.