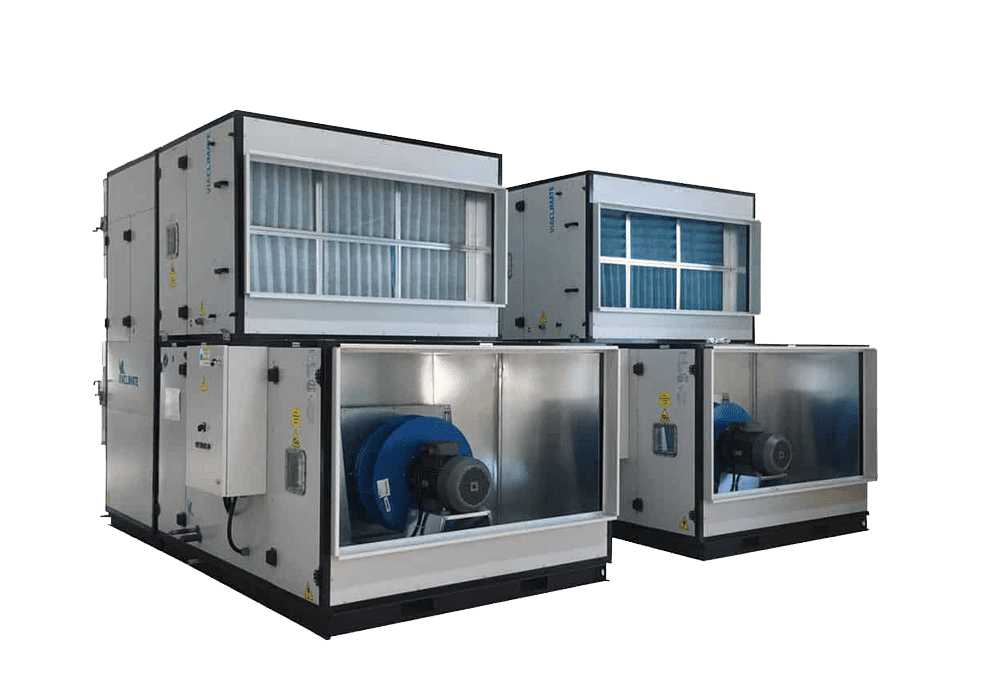

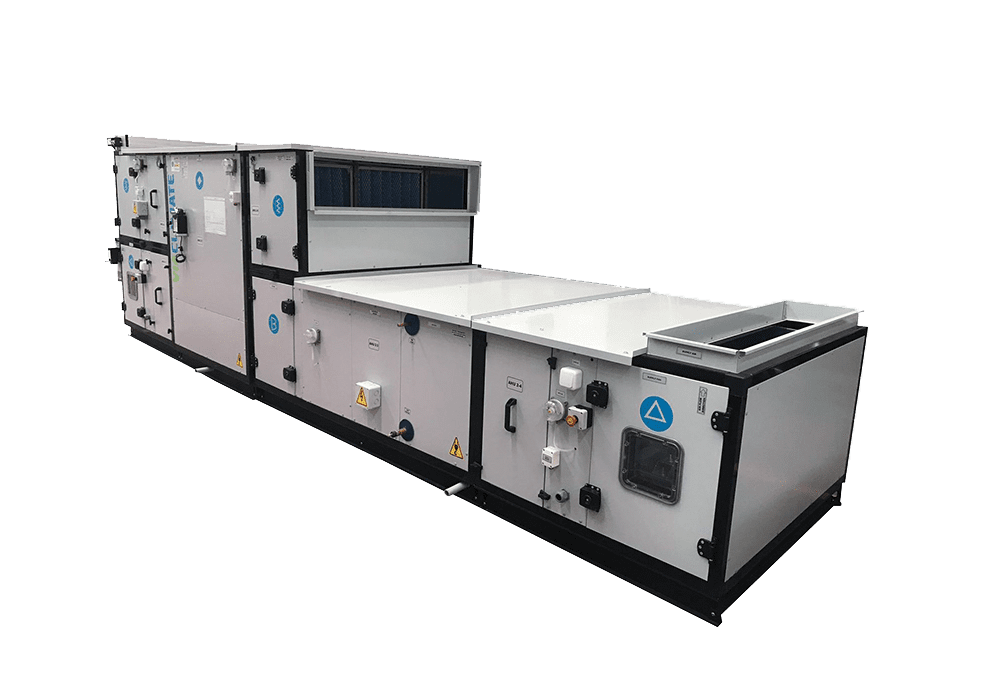

Hijyenik Paket Klima

Viaclimate markalı hijyenik paket klima çeşitleri hijyenik ortamların taze hava beslemesi, ortam havasının egzozu, ısıtma, soğutma, nemlendirme, hava filtreleme, ısı geri kazanımını tek bir ünite içerisinde gerçekleştirir.

Viaclimate markalı hijyenik paket klimalar düşük işletme maliyetiyle, yüksek verimle çalışmaya olanak sağlar. Hijyenik paket klimalar elektrik otomasyonu ve kompakt dizaynları sayesinde tak-çalıştır mantığında uygulamaya yönelik kullanılma uygun cihazlardır.

Viaclimate markalı hijyenik paket klimalar iki çeşittir.

- 100% Taze hava Şartlandırıcı Hijyenik Paket Klimalar

- 100% Taze Havalı Isı Geri Kazanımlı Hijyenik Paket Klimalar